Heat shrink tube sectional expanding machine:The sectional expanding equipment includes rotary oven, tube cutting device, expansion molds, inflator, cloth bags and cooling device. The rotary oven is used to heat the heat the tube. After heating, the tube is evenly expanded in the expansion mold by the inflator and the cloth bag, and then formed after cooling. The tube cutting machine is used to trim the size of the tube, and the incision is more neat. By this method when the tube is expanded, the force on each part is more balanced, which reduces the occurrence of defects such as cracks and uneven wall thickness, which is beneficial to improve the sealing and mechanical properties of the heat shrink tube after expansion.

◆ Equipment list and parameters

Equipment name | Size | Qty |

Rotary oven | Capacity:16pcs Installed power:8.5±1kw Rotation motor: 1.5kw Heating temperature: 140-180℃ PLC control, human machine interface, the rotation speed can be set, and the in-position detection automatically stops the rotation. The oven door is controlled by pneumatic buttons. | 1pc |

Tube cutting device | SH-1700, Pneumatic | 1pc |

Cooling device | Maximum operating 4 sets of molds at the same time. Water temperature: 20±3℃ | 1pc |

Expanding mold | Customized | 1set |

Cloth bags | Customized | |

Inflator and accessories | Customized |

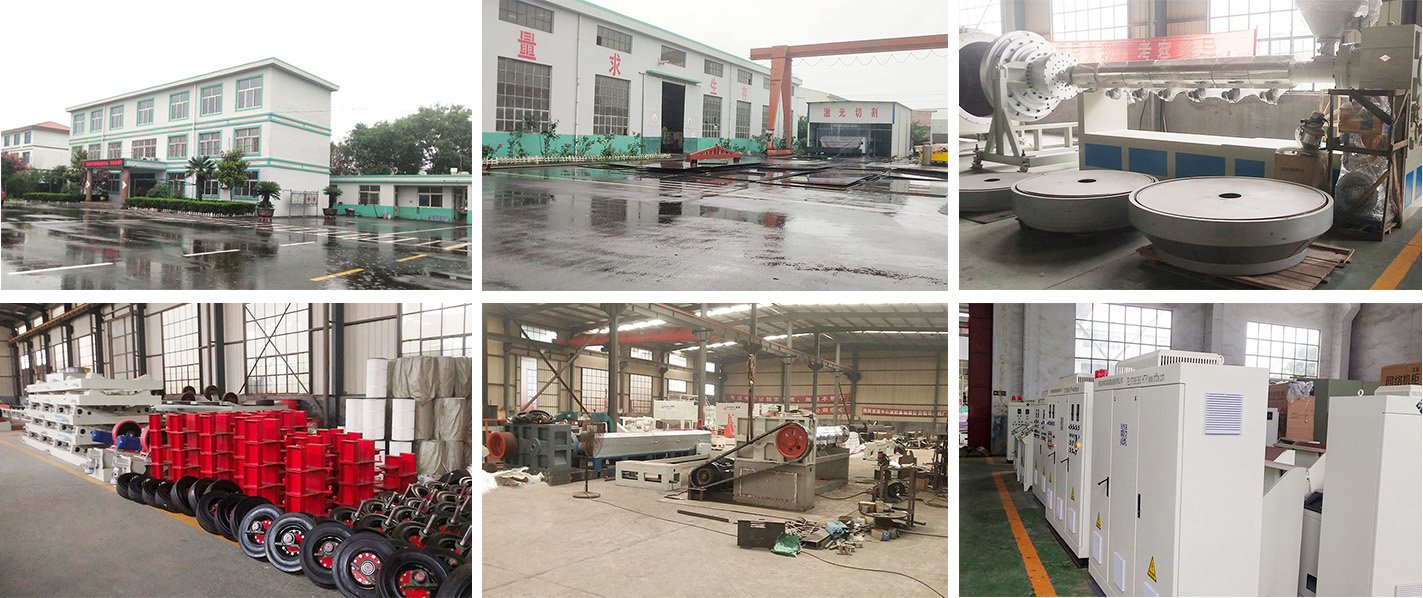

◆ Our Factory

If you have any needs , please fill out the form below and we will contact you as soon as possible.

PLEASE SUBSCRIBE TO OUR EMAIL AND WE WILL REPLY TO YOU AS SOON AS POSSIBLE.