ABS plate production line is used to produce ABS plastic plate/sheet with a width of 1200-2400 mm and a thickness of 0.5-6 mm. After secondary thermoforming, the produced sheet is mainly used to make car dashboard, interior door trim, shell of the scooter or golf car, etc. It can also be used to produce various trolley cases, luggage, etc.

Production line configuration

◆ SJ-150/35 single screw exhaust extruder,

◆ Siemens motor,

◆ High torque hard tooth surface reducer,

◆ Hydraulic screen-filter changer,

◆ shaped extruding head,

◆ Vertical three-roll calender,

◆ Stainless steel cooling bracket with wide-width adjustable trimming device,

◆ Rubber roller tractor,

◆ Automatic sizing shearing machine.

According to customer requirements, the line also can be equipped with an online leather covering device, a three-in-one water temperature controller.

The production line adopts three-dimensional electric control cabinet, Omron intelligent temperature controller, Siemens low-voltage electrical appliances, and inverters of well-known brands.

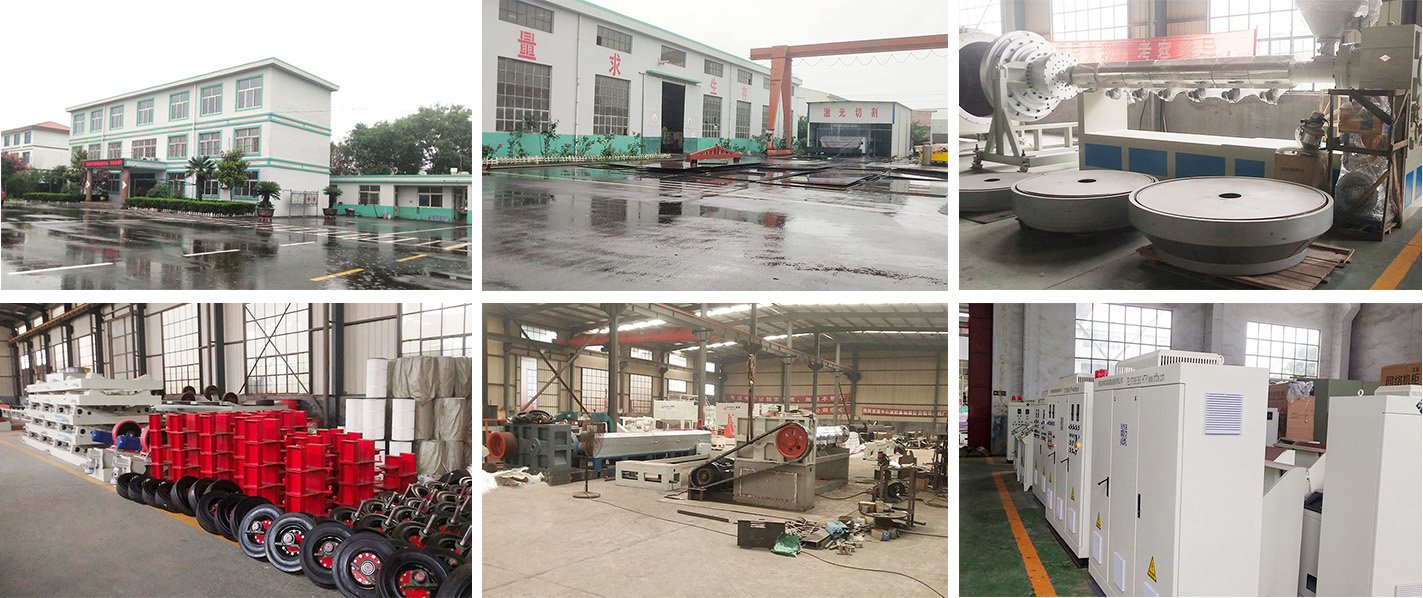

◆ Our Factory

If you have any needs , please fill out the form below and we will contact you as soon as possible.

PLEASE SUBSCRIBE TO OUR EMAIL AND WE WILL REPLY TO YOU AS SOON AS POSSIBLE.