The hollow wall winding pipe equipment is advanced in design, high-end configuration, reliable in operation, and has a long service life, producing the structured wall winding pipe ranging from 200mm to 4000mm and ring stiffness of 2- 8kN/m².

◆ Product introduction

HDPE structured wall winding pipe has been successfully used as a drainage pipe to replace cement pipe and cast iron pipe, and has a broad market prospect.

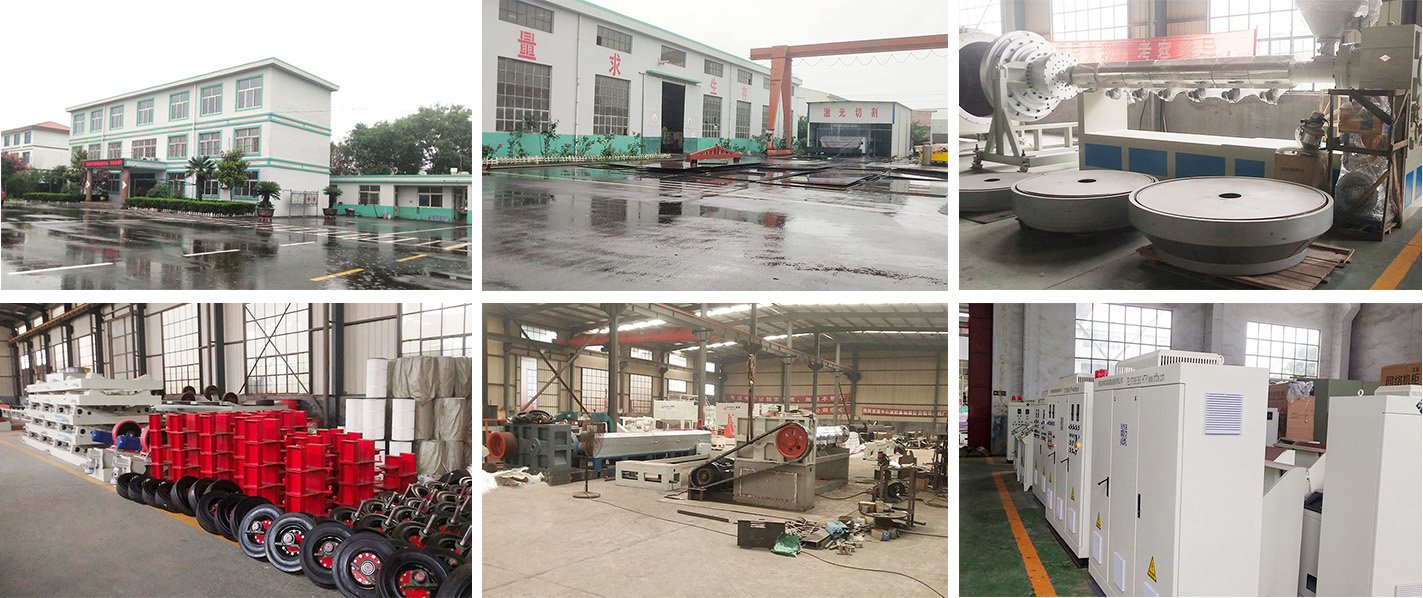

Our company is a authoritative manufacturer of large-diameter structured wall winding pipe production lines, with strong technical advantages and rich installation experience.

The equipment is advanced in design, high-end configuration, reliable in operation, and has a long service life, producing the structured wall winding pipe ranging from 200mm to 4000mm and ring stiffness of 2- 8kN/m².The output of the same model is much higher than the level in the same industry. Especially, it has rich experience in large-diameter models, which can meet the needs of large-scale high-end customers at home and abroad.

The performance index of the production line has reached the international leading level.

◆ Features

High-efficiency single-screw extruder to ensure high-efficiency and high-quality extrusion.

Using compound head, spiral forming, the exquisite mechanism and the unique design ensure the high quality of the product.

Easy to operate, stable and reliable.

◆ Pipe Applications

– Storm Water Management./ Stormwater Attenuation Application / Storm water pipelines.

– Sewerage Pipelines

– Drainage Pipelines

– Culverts

– Pipe rehabilitations

– Landfill drainage/Leachate

– Mine drainage.

– HDPE manholes. / Manhole Drops

– Floats

– Irrigation

◆ Special pipe fitting connection, convenient connection and economical construction.

The product that can be designed is multi-layer co-extrusion: the inner and outer walls of the tube are covered (the covering layer is pure raw material, and the inner layer is recycled material)

Model | Dia(mm) | Extruder | Installed power, kw | Capability kg\h | Dimention | ||

Model | L\D | Motor power, kw | |||||

HC-800 | 200-800 | SJ75\33 SJ65\33 | 33:1 | 55 30 | 145 | 290 | 23*10*3.2 |

HC-1200 | 300-1200 | SJ90\33 SJ65\33 | 33:1 | 75 37 | 175 | 380 | 24*10*3.5 |

HC-1600 | 800-1600 | SJ100\33 SJ75\30 | 33:1 | 110 45 | 250 | 540 | 26*11*5 |

HC-2200 | 1200-2200 | SJ100\33 SJ75\30 | 33:1 | 132 55 | 280 | 740 | 32*16*6 |

HC-2600 | 1400-2600 | SJ120\33 SJ75\33 | 33:1 | 132 75 | 260 | 500 | 39*17*6.5 |

HC-3000 | 1800-3000 | SJ120\33 SJ75\33 | 33:1 | 160 75 | 330 | 820 | 42*17*7 |

HC-4000 | 2000-4000 | SJ150\33 SJ90\33 | 33:1 | 250kw 90kw | 440 | 1200 | 48*20*7.5 |

◆ Our Factory

If you have any needs , please fill out the form below and we will contact you as soon as possible.

PLEASE SUBSCRIBE TO OUR EMAIL AND WE WILL REPLY TO YOU AS SOON AS POSSIBLE.